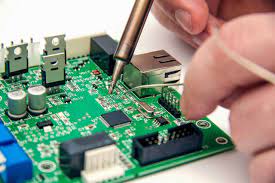

PCB is required for the mechanical support of any type of electronics product. This is in the form of a card or a board which is made up of thin metal or hard plastic commonly known as the insulator. The chips of the electronic devices are mounted on this card or the board. The PCB is used in the smallest device like the mobile to larger electronics devices like the computer and the television. The PCB which has not been fitted with any component is called PCB as it is raw but when the electronics components are mounted it is called PCB assembly service.

Why is PCB Assembly Service Required?

In the modern world, technology is developing at a fast rate so many changes are taking place in the operational functions of all the electronics devices so most of the electronics devices which are of the old model are becoming outdated and the components or the parts are not available easily. At this juncture, it becomes necessary to either get a new model or update the existing model of the electronics goods whether at the office or home.

The resale value of the old models is very low so if the PCB assembly service is changed and the new PCB board or card which is mounted with the latest chips is fitted in the electronics device then the device can be updated at a lower cost than purchasing a new model. These boards are available in three types which are single-sided, double-sided, or multi-layered.

Through Hole PCB Assemblyis one of the required manufacturing processes for the production of consumer electronics products. In the past, consumer electronics original equipment manufacturers (OEM) assembled PCBs in-house. But due to the rapid development of surface mount technology and innovative manufacturing processes and equipment, PCB assembly is now often outsourced to contract electronics manufacturers who specialize in PCB Assembly.

There are advantages to utilizing a PCB Assembly Service. They include:

- Less Capital Investment. To assemble PCBs in-house requires a large capital investment in manufacturing facilities, lines, and machinery as well as the hiring and training of qualified personnel. As a result, it can be a long return on investment (ROI). Using an outsourced service just makes financial and economic sense.

- Cost Per Unit Benefits. A consumer electronics OEM can benefit from “economies of scale” by leveraging the capital investments made by a PCB Service in facilities, equipment, and personnel to generate reductions in cost per unit, which can make them more competitive in the marketplace.

- Product Design Improvements. PCB Services sometimes include electronic design services as part of their assembly costs. These design services can verify electronic designs and make suggestions on PCB improvements, which translates into superior products with higher quality at a lower cost to you.

- The Value of Extensive Experience. Outsourced PCB services possess extensive experience in mass-producing PCBs at the lowest possible price even for tight deadlines. This value cannot be underestimated.

- Quality Assurance. In today’s competitive marketplace, quality assurance is critical to reign in unexpected costs and maintain customer satisfaction. Not all consumer electronics manufacturers have the quality systems and resources as well as the test equipment to guarantee the quality of theirThrough Hole PCB Assembly. Conversely, PCB manufacturers utilize a variety of quality systems and procedures to ensure quality assurance. In addition, they have the business relationships to procure top-quality electronic components. This is critical because to trust the final product, one must trust the components that are used to produce it.

Customers today use the Internet to research not only the products and services of a consumer electronics company but also its business reputation. If a consumer electronics company becomes known for producing less than high-quality products, this could result in irreversible damage to its business reputation.

This is central to what a PCB Service can do for you: lower your costs and guarantee your product quality to enhance your business reputation. It only makes sense to partner with a contract electronics manufacturer to produce your PCBs.