Filling machine is considered to be one of the most important things to be used in a liquid industry. Since we can use this to measure the predefined value of a product, it is very important. Are you looking for a liquid filling machine? But do you find yourself confused doing intense research on google? Choosing the tight filling machine can be a little tricky. So, whichever industry you come from, there are several things to consider while finding the best liquid filling machine. Below are the things you should check while choosing a cartridge filling machine.

1.Filling Speed

The faster the filling machine is, the better it is. Does your production require a high volume output? Look to maximize your productivity. Choose a fully automated filling line that will output several bottles per minute (BPM). It will mind filling, capping, and labeling- with just a push of a button.

On the other hand, if cost is a factor and your production demand is not that high, you can focus more on a tabletop pump, piston, or peristaltic filler. It can be expanded with automation packages with your business growth. Choose a filling manufacturer who understands your individual production needs and affordability. Invest in such a way that ensures maximum benefit in the immediate future. Let the cartridge filling machine pharmaceutical be a part of an implementation strategy that grows with your business.

2.Type of Liquid Product

It may sound simple but consider the type of product you deal with. Water, oil, soda, soft drinks – all are different from each other with individual filling needs. You probably require a sterile environment when you deal with pharmaceuticals, diagnostic or biotech products. When you deal with specialty chemicals, consider the nature of the product if it is flammable or explosive. You need different types of containers for various liquids.

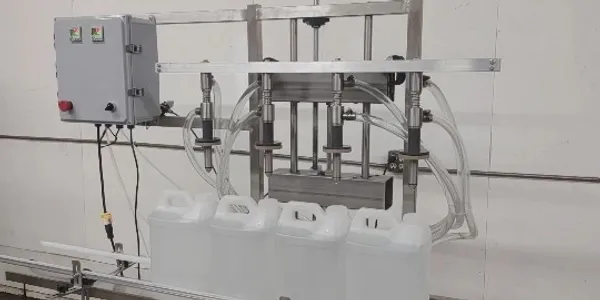

3.Type of Container

There is an endless variety of containers regarding types and sizes. A specific type you choose can influence the kind of equipment suited to fill it. Newcomers often overlook the liquid packaging space. The cartridge filling machine pharmaceutical you select must be ready to accommodate the containers you use. Check the material your containers are made of. Check the shapes and sizes of the container. Choose a filling machine that goes well with them.

4.Cleaning and Changeover

Not all filling equipment is created equal when it comes to cleaning and changeover. Some machines come with CIP or a clean-in-place facility. But this system often falls short in efficiency. Ineffective cleaning and disinfecting can cause cross-contamination. You may not get sufficient access to the surface without disassembly. Check how good the machine is at cleaning.

In terms of changeover, check if the machine is good enough to deal with different types of products. The equipment efficiency can make or break the operation. That depends upon the nature and functional qualities of the machine.

Conclusion

Since a filling machine is one of the most important things in a liquid industry, you need to be careful while you choose one for your company.As you look for the right cartridge filling machine pharmaceutical, you get to check a lot of variety in the market. The more options you face, the more confused you feel. Consider a few less tangible factors as you navigate the space. Check how responsive they are during and after you contact them. If they are willing to solve your queries. How helpful they are during the installation of the machine. If they are still helpful when you face issues while using. Choose to buy your filling machines from a manufacturer who gives this Sort of support.